|

Thermaguard™

We have been producing heat-resistant coatings since 1965. Even before the laser was invented, we were producing marking paint for blast furnaces.

In 2013, our range was expanded with the Thermaguard™ line, especially for C.U.I. (corrosion under insulation).

What is unique about our products is that they harden at room temperature, are available in various colours and are produced and therefore quickly available from Leeuwarden.

For more information: engineering@zandleven.com or 31 (0)58 -2677502

|

|

|

Products

Thermaguard™ CUI 300

Thermaguard™ CUI 300 is a unique inorganic single component, ambient curing polysiloxane coating formulated specifically to provide corrosion protection to under insulation environments where wet & dry cycling can occur.

Novel technology which offers solvent free (100% solids), ultra-low VOC for demanding environmental regulations and safety aspects during hot application. The coating conforms to the NACE SP0198-2010 classification for

Corrosion Under Insulation (CUI) in both cryogenic & elevated temperature applications.

Through specific formulation technology Thermaguard™ CUI 300 can withstand temperatures from -196 to 300oC, fully curing at ambient conditions eliminating the need for heat curing prior to service. Thermaguard™ CUI 300 has

exceptional resistance to thermal cycling, hot saline water immersion & chemical exposure throughout its operating temperature range.

Thermaguard™ CUI 300 can be used in both OEM (shop application) & maintenance work due to having surface tolerance to rusted steels, which have been marginally prepared (St 2/3). Additionally, the product can be applied in

service to hot equipment operating up to 200oC, removing the need for plant shut down periods.

Thermaguard™ CUI 650

Thermaguard™ CUI 650 is a novel, single component, ambient curing polysiloxane coating formulated specifically to provide corrosion protection to under insulation environments where wet & dry cycling can occur. The coating conforms to the NACE SP0198-2010 classification, inert multi polymeric matrix coatings for Corrosion Under Insulation (CUI) in both cryogenic & elevated temperature applications.

Through specific formulation technology the product can withstand temperatures from -196 to 650 °C, fully curing at ambient conditions eliminating the need for heat curing prior to service. The product has exceptional resistance to thermal cycling, hot saline water immersion & chemical exposure throughout its operating temperature range.

Thermaguard™ CUI 650 can be used in both OEM (shop application) & maintenance work due to having surface

tolerance to rusted steels which have been marginally prepared (St 2/3). Additionally, the product can be applied in

service to hot equipment operating up to 260 °C, removing the need for plant shut down periods.

|

|

|

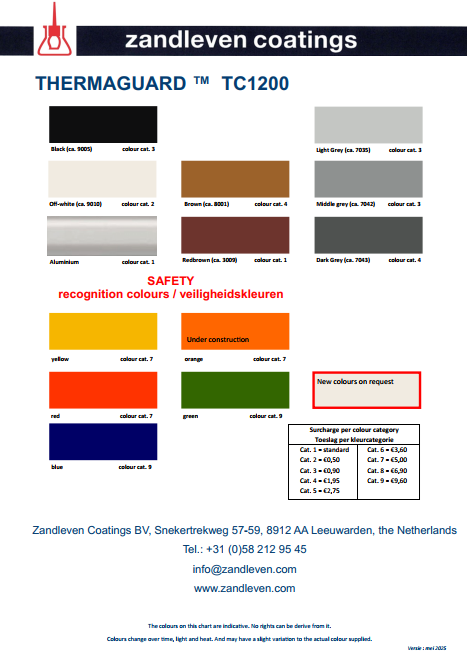

Thermaguard™ TC 1200

Thermaguard™ TC 1200 is a single component, ambient curing polysiloxane topcoat which is thermally colour stable at elevated temperatures. The product can be operated within cryogenic -196 to 650 °C temperature range.

Completely inorganic chemistry results in ultra-high performance regarding operating temperature & UV

degradation.

Available in a full range of safety colours, RAL shades& custom colours formulated upon request. The product can be applied over suitably primed steel surfaces such Thermaguard™ SAL 600 anti-corrosion coating. Can be applied in service up to 130 °C substrate temperature

|

|

|

Thermaguard™ SAL 600

Thermaguard™ SAL 600 is a high temperature resistant siloxane aluminum, single component, ambient curing, coating which is designed to provide corrosion protection throughout a range of temperatures from -196 to600 °C.

Formulated coating to provide corrosion protection to steel equipment which is exterior exposed andoperating at elevated or cryogenic temperatures. Designed to withstand thermal cycling throughout its operating range while maintaining corrosion protection to steel substrates

|

|

|

| |

|

|

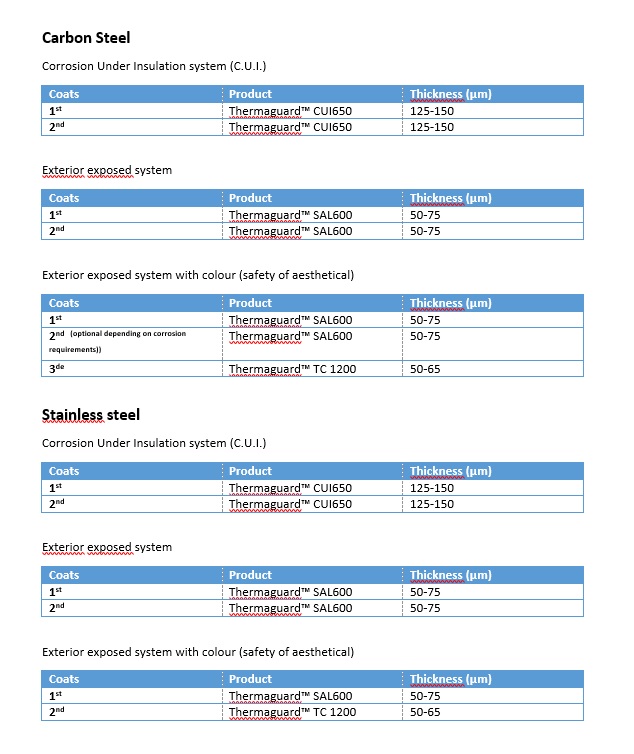

Example systems:

Refer to the technical data sheets (TDS) for the correct method of pretreating, product properties and application.

Please contact our technical department for advice. |

|

|

|

|

|